How Does Energy Efficiency Save Costs in Ice Cream Making Machines

In the world of ice cream production, energy efficiency plays a crucial role in reducing operational costs and enhancing sustainability. JELUMB Refrigeration Equipment (Shanghai) Co., Ltd, a leading manufacturer in the refrigeration industry, is at the forefront of developing energy-efficient ice cream making machines. This article explores how energy efficiency can lead to significant cost savings and discusses JELUMB's contribution to this evolving landscape.

The Importance of Energy Efficiency

Energy efficiency refers to using less energy to perform the same task. In the context of ice cream making, it involves optimizing the machinery and processes to minimize energy consumption while maintaining or enhancing productivity. This is particularly important as energy costs constitute a substantial portion of the operational expenses in ice cream production.

With rising energy prices and increasing environmental concerns, manufacturers are compelled to adopt energy-efficient technologies. JELUMB has recognized this need and has developed state-of-the-art refrigeration systems that excel in energy efficiency, thereby offering substantial cost savings to ice cream producers.

How Energy Efficiency Translates to Cost Savings

There are several ways in which energy efficiency can lead to cost savings in ice cream making machines:

Reduced Energy Bills: By consuming less electricity, energy-efficient machines lower the monthly utility bills. This directly impacts the bottom line, allowing businesses to allocate resources to other critical areas.

Longer Equipment Lifespan: Energy-efficient machines often experience less wear and tear, leading to a longer operational life. This reduces the frequency of replacements and repairs, further cutting down costs.

Improved Productivity: Efficient machines can produce more ice cream in less time, increasing the overall output without a corresponding increase in energy consumption.

Enhanced Sustainability: By reducing energy usage, these machines help lower the carbon footprint, aligning with global sustainability goals and potentially qualifying for environmental incentives and rebates.

JELUMB's Innovations in Energy Efficiency

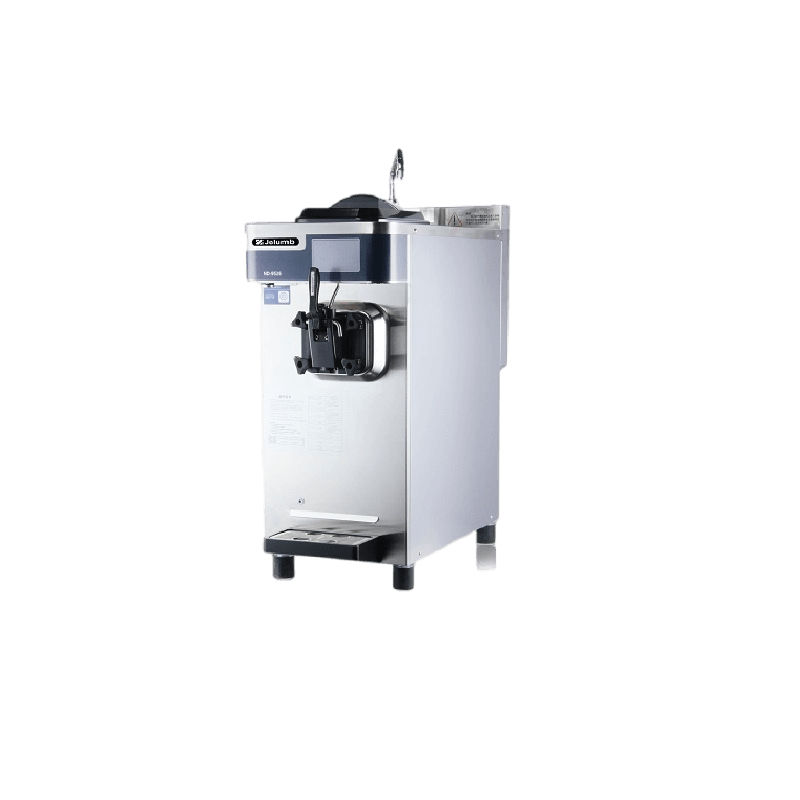

JELUMB has been pioneering innovations that set benchmarks in energy efficiency within the refrigeration sector. Their ice cream making machines are equipped with advanced technologies that optimize energy use without compromising on quality or performance.

Key Features of JELUMB's Energy-Efficient Machines

JELUMB's ice cream machines incorporate several key features that enhance energy efficiency:

Variable Speed Compressors: These compressors adjust their speed based on the cooling demand, ensuring that only the necessary amount of energy is used at any given time.

Eco-Friendly Refrigerants: JELUMB uses refrigerants that have a lower global warming potential, reducing the environmental impact while maintaining high efficiency.

Advanced Insulation: Improved insulation techniques minimize heat loss, ensuring that the machines retain the desired temperature with less energy.

Smart Controls: Automated systems and sensors optimize the machines' operations, adjusting settings in real-time to maintain efficiency.

Case Study: JELUMB's Impact on Ice Cream Production

Consider a mid-sized ice cream manufacturer that switched to JELUMB's energy-efficient machines. The transition resulted in a 20% reduction in energy consumption, translating to thousands of dollars saved annually. Additionally, the manufacturer reported increased production capacity and improved product quality, attributing these improvements to the advanced features of JELUMB's machines.

Industry Trends and Future Outlook

The refrigeration industry is witnessing a shift towards more sustainable practices, driven by both regulatory pressures and consumer demand for environmentally friendly products. Energy efficiency is at the heart of this transformation, with companies like JELUMB leading the way.

Looking ahead, the industry is expected to see further advancements in technology, including the integration of artificial intelligence and machine learning to enhance efficiency. JELUMB is poised to continue its leadership by investing in research and development to bring cutting-edge solutions to the market.

Challenges and Considerations

While the benefits of energy-efficient ice cream making machines are clear, there are challenges to consider:

Initial Investment: Energy-efficient machines may have a higher upfront cost, which can be a barrier for smaller manufacturers. However, the long-term savings often justify the investment.

Training Requirements: Operators may need training to effectively use and maintain advanced energy-efficient machines, necessitating additional resources.

Technological Adaptation: Keeping up with rapid technological changes can be daunting, requiring manufacturers to stay informed and adaptable.

Conclusion

Energy efficiency in ice cream making machines is not just a trend but a necessity for cost savings and sustainability. JELUMB Refrigeration Equipment (Shanghai) Co., Ltd has demonstrated its commitment to this cause by developing innovative solutions that benefit both the environment and the bottom line. As the industry continues to evolve, embracing energy-efficient technologies will be crucial for manufacturers aiming to remain competitive and responsible.

In conclusion, the adoption of energy-efficient ice cream making machines represents a strategic investment that can yield significant financial and environmental returns. Through its pioneering efforts, JELUMB is setting a new standard for excellence in the refrigeration industry, paving the way for a more sustainable and cost-effective future in ice cream production.

EN▼

EN▼ CN

CN FR

FR IT

IT KR

KR

Leave a comment